Last week we bought our iPad 4. I can tell you, my family and me are very enthusiastic about its performance and superb screen resolution. However, this is not our first electronic appliance in our home. Besides this tablet we use three cell phones, two laptop computers, a printer, a TV screen, a DVD recorder, a hifi set, two photo cameras, etc.

I know, many of my friends and family have all this stuff too. This made me think about a significant material scarcity issue: all these electronic appliances consume both much and a myriad of metals, ceramics and polymers, for example such as copper, gold, silver platinum, rare earth elements, tin, lead, epoxy, (flame retardant) PC-ABS, PC, silicon, phosphor, aluminum, TiO2, BaTiO3 and glass. Up to 60 different elements are applied in complex designed electronic appliances and this number is still increasing due to the desired increased functionality and performance. Due to the increasingly shorter product life cycle in the consumer electronics market, we dispose more and more electronic waste, shortly e-waste. But, how big is the problem? What do we do with this waste and how could we effectively re-use or recycle it?

Some facts about e-waste

I have a technical - commercial background, so I am a lover of numbers. We globally dispose about 50 million tons e-waste. The US seems to be the number one and disposes about 3 million tons e-waste, China 2.3 million tons (2010) [1]. Also interesting is that US Environmental Protection Agency estimates that only 15-20% of e-waste is recycled. The majority of these electronics go directly into landfills (including countries like Ghana and China) and incinerators [1].

It is also interesting to find out how much valuable materials are present in e-waste. In accordance to the US Geographical Services, the US dispose about a 130 million cell phones annually. In Europe this is about a 100 million cell phones, so pretty similar as in the US. The disposal of 130 million cell phones corresponds with 14,000 tons e-waste. This contains 2,100 tons of copper, 46 tons of silver, 3.9 tons of gold and 2 tons of palladium. In other words, a ton cell phones contains about 0.28 kg gold. This is about 50 - 60 times more concentrated than in gold ore, depending on local geology [2]. My Nokia 6330 cell phone weighs about a 100 grams. Assuming that my Nokia cell phone contains a similar weight ratio of precious metals as mentioned above, the value of the precious metals amounts to about USD 2.25 (based on the current market spot prices). That's not pretty much for a cell phone that originally costed about EUR 80 (USD 104), also suggesting that providing functionality offers more added value than the value of raw materials itself.

The need for effective and safe recycling

I think there are three major reasons for an effective and safe recycling e-waste loop.

At first, from scarcity point of view, there is certainly a need for raw material recovery. During the next 10 - 20 years we face serious mining problems such as gold, silver, tin, indium and to a lesser extent copper [4]. As a consequence, further price hikes, increased price volatility and supply chain issues could take place in the future. Therefore, the recycling sector could be become an increasingly interesting business opportunity: recycler of iPads and cell phones Environcom in the UK makes 2 million GBP profit on a 13.5 million GBP turnover and is expected to grow rapidly [5]. Rare earth elements such as neodymium and europium are subject to foreign policy, as China currently controls up to 97% of all rare earth elements on our planet. E-waste is a relatively concentrated source of critical elements in comparison to the concentration of those elements present in the original mineral ores.

Secondly, the disposal of electronic appliances has significant safety and environmental consequences. Once e-waste is dumped like in China (Guiyu) and Ghana, soaring levels of toxic heavy metals and organic contaminants were detected by Greenpeace in soil, dust, river sediment and ground water samples [1]. In these huge e-waste centers burning of e-waste seems to be a quite common practice. This exposes the "workers" (including children) to a variety hazardous substances during recycling operations. For instance, inhaling or digesting lead dusts or fumes can cause birth defects, blood damage and affecting the neurological system [3]. It is very sad that 82% of Chinese Guiyu children have lead containing blood levels that exceeds on average the maximum allowable lead content with 49%!

Finally, manufacturing metals is a relatively energy intensive operation. Recycling of metals can save a lot of energy in comparison with virgin metals.

Towards better e-waste sustainability solutions

E-waste sustainability solutions are not easy and need a multidisciplinary approach throughout the complete chain. The solutions are not only technical I think. Our consumer behavior and the supply chain of e-waste must be taken into consideration as well. Below some considerations and ideas.

Many computers or TV screens are already recycled. However, the big challenge in e-waste recycling of the so-called printed circuit boards (PCB's). PCB's are in fact complex composites of thermoset resins containing all kinds of metals such as copper, gold, silver, tin applied bond paths, solder alloy and electronic components. In order to obtain a long-term reliable electronic appliance, the PCB design and bonding of the components is robust and in many cases resistant to combined mechanical, electrical and/or temperature loadings during the service-life of the device. However, after disposal, the dis-assembly (recycling) of these PCB's is pretty hard. Therefore we need PCB's with easy bonding and debonding properties to combine a reliable working during the aimed service life of the product (about 2 years for a simple cell phone) and easy recycling performance. New Diels-Alder bonding on demand technology might provide solutions for these requirements. There are now new reversible epoxy based adhesives developed which show poor bonding properties at elevated temperatures (around 100 oC) and high bonding properties from around 60 oC to room temperature. Further investigation of bonding-on-demand technology in PCB design is required to improve the recycling efficiency.

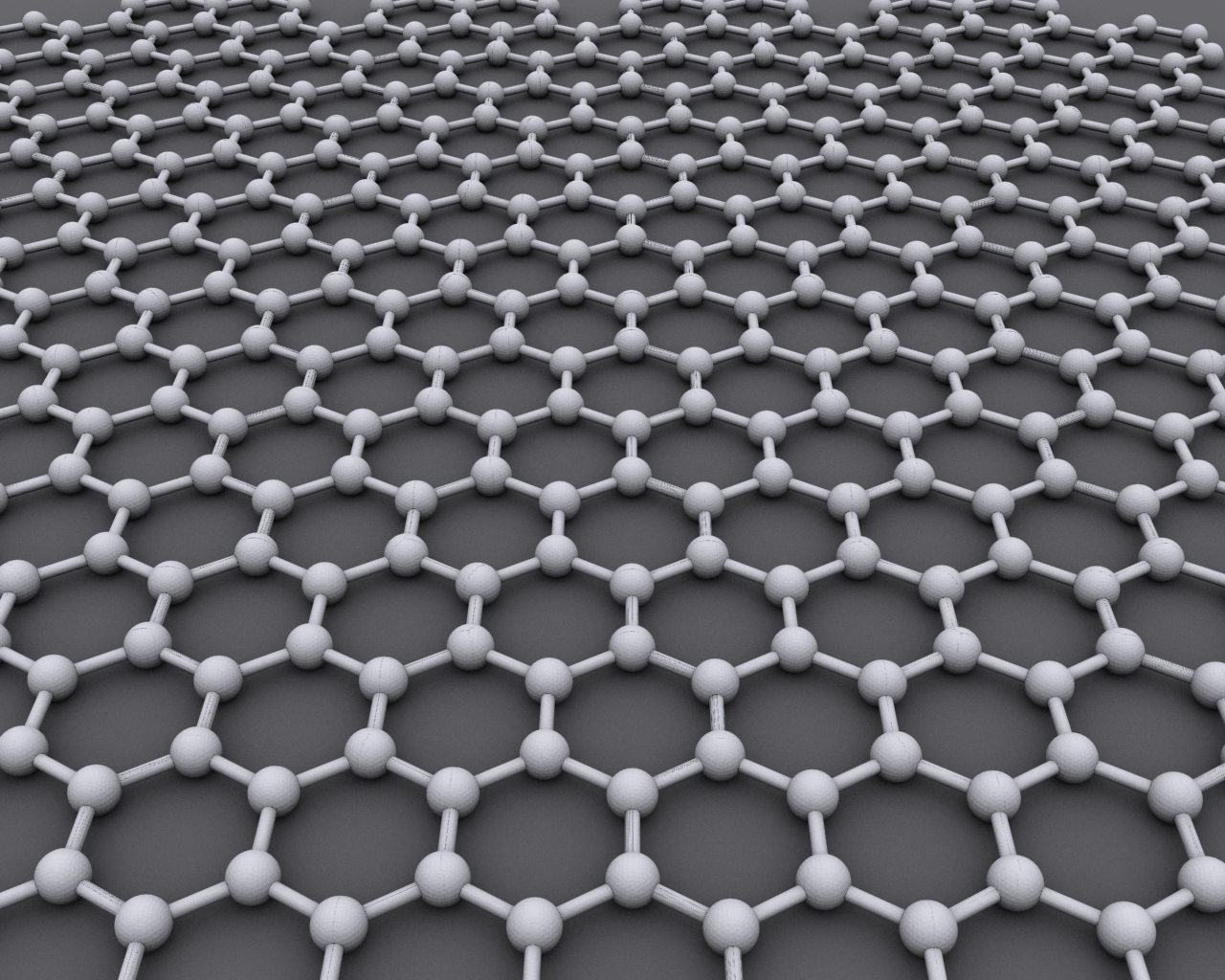

Another way to improve the sustainability of e-waste is to substitute a scarce material by a lesser scarce material. For example, Indium and Gallium could be substituted by graphene, an atom thick, 2D graphite-like carbon structure with exceptional strength, heat and electrical conductivity. Platinum could be substituted by silver. However, careful consideration is required from performance point of view.

Finally, scarcity is also dependent on our (consumer) behavior. Is it really necessary to buy the latest smartphone or iPad? Not really, I think. So we should demand better, long-lasting products which enables us for easy self-replacing critical hardware components. For example the replacement of the old processor IC by a faster new IC in case the iPad or smartphone becomes really "slow". Quite differently, we could also decide to buy an iPad or laptop computer with our neighbors and share the use of it. In fact a shift from Personal Computer (PC) to Shared Computer (SC). Another idea: we should better consider our disposal behavior. More and more points for collecting e-waste are available in the retail sector to recycle e-waste properly. Despite more and more people are aware of it, about 70% of all e-waste is still landfilled or incinerated. So our disposal behavior still needs a good and positive incentive to be more effective. As electronic appliances contain a myriad of valuable materials, these materials represent a certain value. Therefore, disposing e-waste should not be free I think. A standard price mechanism for all disposed appliances could help to get more consumers actively involved to recycle their e-waste. This is a must to recycle e-waste even more successfully.

I wish you all a good, healthy and green 2013!

Jan Willem

Literature links

[1] http://en.wikipedia.org/wiki/Electronic_waste

[2] http://rareearthdigest.com/ree-news/news-global/64-newsgrncell07122010.html

[3] http://www.sentryair.com/solder%20fume.htm

[4] www.metaalmagazine.nl/download/Rapport_Schaarse%20metalen.pdf

[5] http://www.guardian.co.uk/environment/2012/mar/16/ipad-recycling-opportunity-uk-firms